co-financed by Centro 2020

co-financed by Centro 2020 Portugal 2020

Portugal 2020 EU European Fund for structure and investment

EU European Fund for structure and investment PME Líder ‘21

PME Líder ‘21 PME Excelência ‘19

PME Excelência ‘19

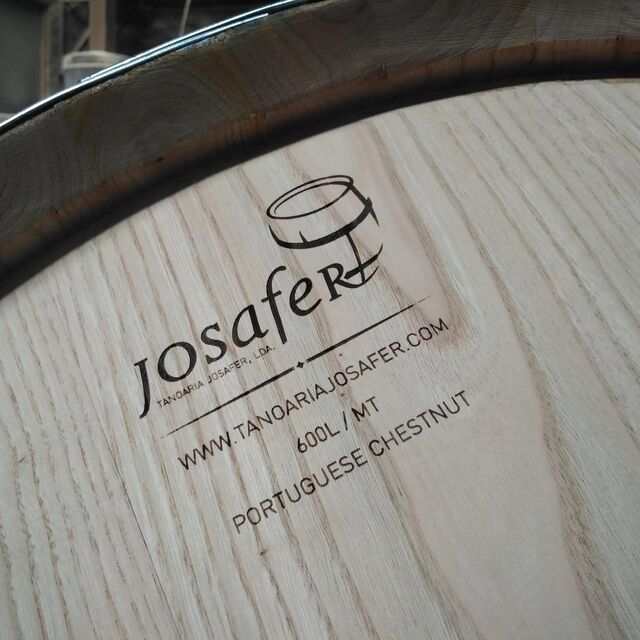

A cooperage rather than a distillery, Josafer was founded in 1962 by current CEO, José António Fernandes and has strong ties to its location - the famous Port Wine region of Portugal. Specialising in the manufacture and repair of barrels and casks for the storage and ageing of the best wines and whiskeys in the world, Josafer diversified in 1990 and is also currently the national leader for export of garden and decorative barrels.

Their ambition is to present products, services and solutions of the highest quality - and with the finest woods, casks and the skill of their team they now have 3 main product lines - Supreme casks, Heritage casks, and Deco casks.

Passing from generation to generation, the company is known for its rigorous training and investment in new equipment, which allows them to continuously improve their current and prospective offering to customers around the globe.

As well as a focus on the 6 senses which they apply throughout their work, they also apply strict controls on quality and client satisfaction and have now become a recognised brand within the spirits industry.

Hearing, smell, taste, touch, sight, but...the essential is invisible with sight. Find your 6th sense...

Interesting Facts

Founded in 1962 by current CEO, José António Fernandes, Josafer have strong ties to their location - the famous Port Wine region of Portugal. Specialising in the manufacture and repair of barrels and casks for the storage and ageing of the best wines and whiskeys in the world, Josafer diversified in 1990 and is also currently the national leader for export of garden and decorative barrels.

Their ambition is to present products, services and solutions of the highest quality - and with the finest woods, casks and skills they now have 3 main product lines - Supreme casks, Heritage casks, and Deco casks.

Passing from generation to generation, the company is known for its rigorous training and investment in new equipment to allow them to continuously improve their current and prospective customers from around the globe.

Their char process uses temperature to transform the organoleptic profile of the wood compounds, providing scents, flavours, and colours that distilleries are looking for in maturation. The char process allows them to caramelise the sugars in the wood and transform its aromatic profile.

Josafer use wood of many types and provenances, dried in the open air for 12-18 months at their facility 5km from the excellent geographical location for this process, just 5km from the Atlantic Ocean.

Their preferred wood types include American Oak, European Oak, Portuguese Oak & Portuguese Chestnut.

As well as a focus on the 6 senses which they apply throughout their work, they also apply strict controls on quality and client satisfaction and have now become a recognised brand within the spirits industry.

Cask World's Highlights

I came across the Josafer Cooperage brand whilst visiting Penderyn Distillery in Wales, UK. Previously we had all been impressed with the Penderyn port cask matured single malt whiskies. There was always something a bit special about them - like a secret ingredient.

If you’ve ever wondered how or why a whisky tastes so special or particularly unique, a major factor could be the cask used for maturation. The type of alcohol that has been previously aged in the cask leaves its flavours within the pores of each wooden stave. With fluctuating temperatures over the seasons, the wood is squeezed and released, allowing for the magic to occur as the distillery’s clear spirit and the cask’s dormant flavours synergise.

Josafer is uniquely located in the famous Porto area of Portugal. The bodegas and vineyards that provide the grapes are on their doorstep. For generations, they have developed close relationships with some of the world’s finest wine and port producers, giving them direct access to freshly emptied casks of superior quality, ripe for maturing whisky. The cooperage also plays a major role in the local community, providing international trade and secure employment while continuing to maintain local traditions.

Sister-brother duo Sandra and Filipe were full of passion and energy as they showed me around their world of wood - demonstrating the time-honoured techniques that make quality coopering a true art form, and encouraging me to savour the aroma of cask after cask - even unwrapping some of their finest vintages. Although not a wine or port expert, I noticed that similar freshness and sweetness that jumps out at us when we enjoy our garden-grown veg instead of mass-produced supermarket offerings.

As our growing global cask portfolio of whiskies continues to mature, we are always on the lookout for the best wood to finish off their journey and provide a remarkable flavour profile when bottled. It is unquestionably here at Josafer, with Sandra and Filipe at the helm, that we will be sourcing our ex-Port and Madeira casks.

Josafer at a glance

Cooperage Name

Tanoaria Josafer

Founders

José a. Fernandes

Cooperage Age

Established 1962

Cooperage Location

Esmoriz, Portugal

The Team

José a. Fernandes - CEO

Filipe Octávio - Sales Manager

Sandra Fernandes - Financial DirectorFacilities

Everything needed to create individual casks to requirements of the customer!

Cask Types

Josafer offer Supreme casks, Heritage casks, and Deco casks. American Oak, European Oak, Portuguese Oak & Portuguese Chestnut, and other interesting wood/previous use types including exquisite ex-port casks. Galvanised or metal hoops, varying sizes and 4 char options - light, medium, heavy and extra heavy.

Cask Storage

Casks are stored on site before logistics and export experience comes into play allowing them to be transferred to the distillery for filling

The Cask Making Process

Step 1: Pre cut wood staves are kept outside to dry for 1-2 years. This allows the wood to bend more easily during the barrel making process.

Step 2: The craftsmen plane the staves on one side to 27mm thick.

Step 3: Next an angle is just into the wood so that the staves will fit tightly together when forming a circular piece.

Step 4. Assembly of the barrel begins before fire is used inside to bend the wood and the rings are hammered around the staves to hold them together.

Step 5. After the rings are on the barrel, the workers toast the barrel using different levels of toast from light to heavy depending on requirements

Step 6. Next they make the barrel heads - first the machine that cuts the head at an angle before a cooper fits the head into the barrel and it's sanded.

Additional Products

Josafer offer a wide range of products in addition to casks - from flower pots and homewares (decorative items, jugs, salad tongs and more) through to hot tubs and even baths. For more details please get in touch!

Current Cask Prices

Varies dependent on type - please contact us for details

Awards

PME Líder ‘21 & PME Excelência ‘19 - The PME Líder and Excelência status is a seal of reputation created by IAPMEI to distinguish the merit of national Small and Medium Companies with superior performance.

Take a look around

Click on an image to view the gallery full screen